METALKOVO a.s.

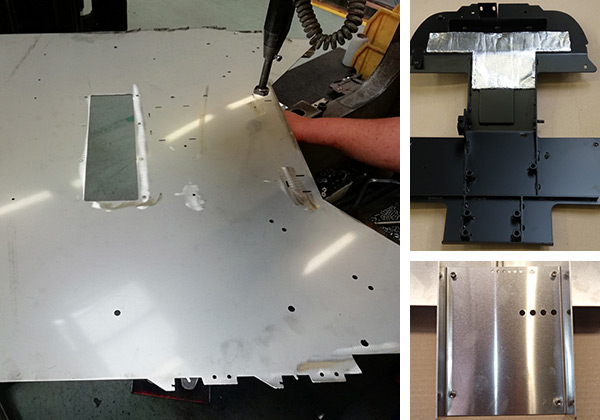

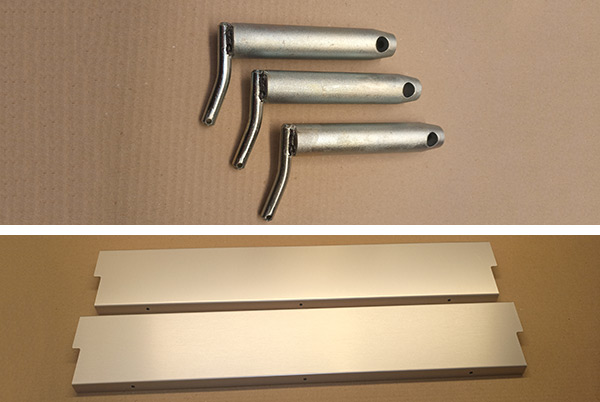

We manufacture sheet metal parts, assemblies, including their welding, painting and assembly.

We are a reliable partner in the field of mechanical engineering.

About us

Although our company METALKOVO a.s. was newly created on 1. 1. 2021, so by taking over the technology and the entire previous management system, including the retention of existing employees who have several years of experience, we can say that we have been operating for more than 6 years as your partner in engineering.

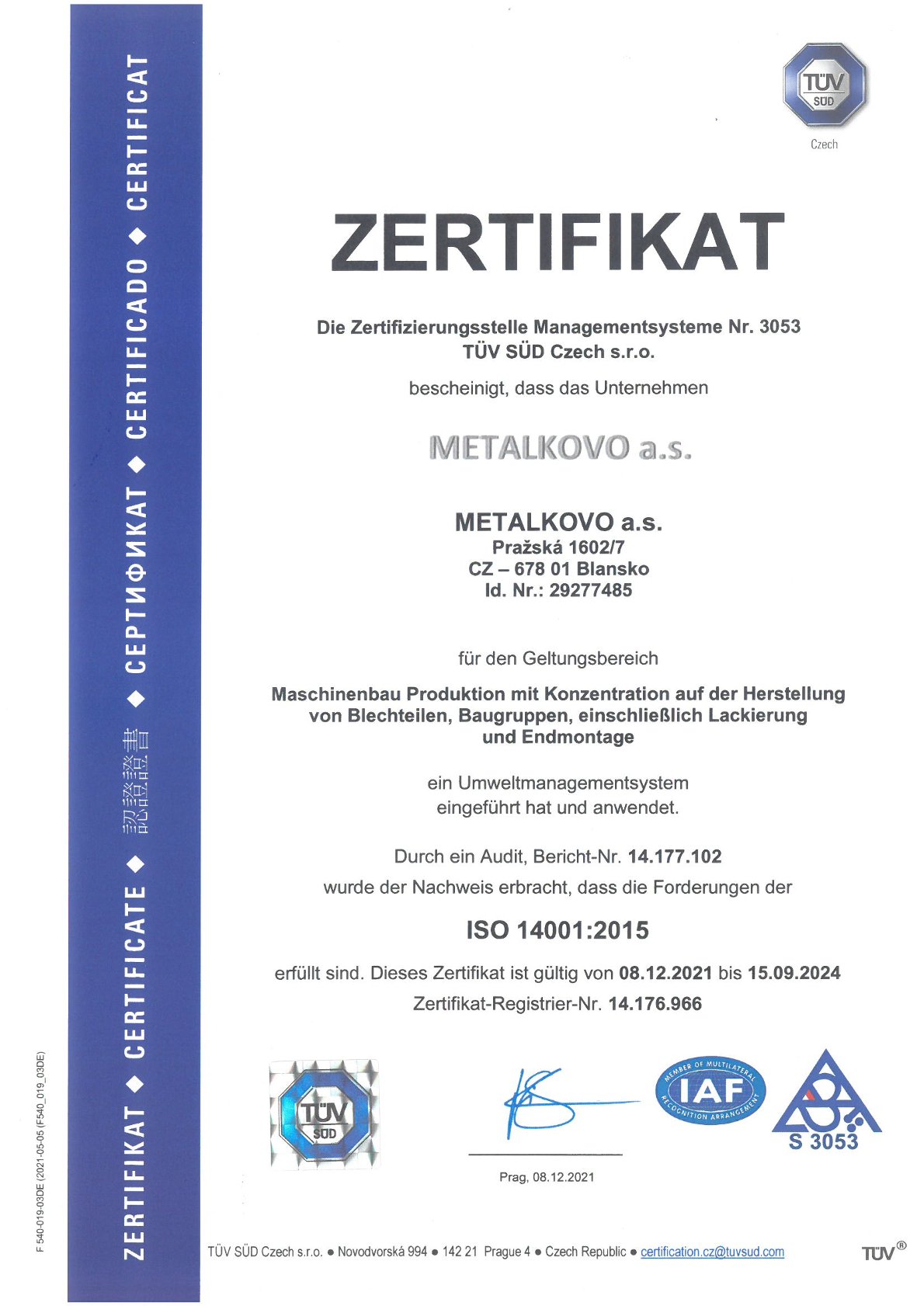

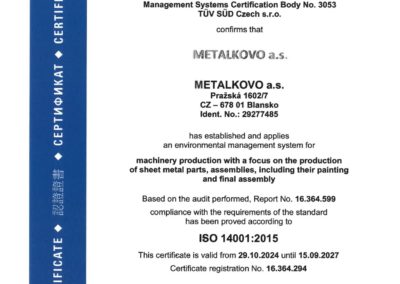

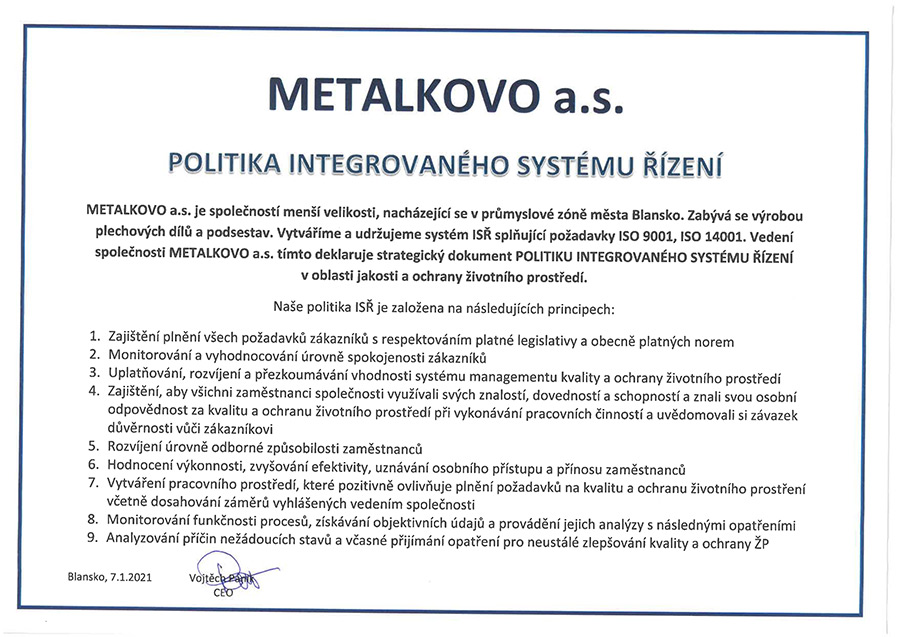

We offer comprehensive processing of CNC and NC technologies on Trumpf machines. We carry out surface cutting and laser cutting, sheet metal cutting and punching at the punching center, sheet metal bending on NC hydraulic press brakes, metal machining, welding in a protective atmosphere of MIG / MAG and TIG (TIG) gases and locksmith production. We are able to realize small-series and large-scale production, including sub-supplies of surface treatments (galvanic galvanizing, anodizing, metalworking, blasting). Testing and inspection takes place according to established standards and individual customer wishes. The company has an integrated quality and environmental policy, including certification – ČSN EN ISO 9001:2016 and ČSN EN ISO 14001:2016.

Manufacturing process

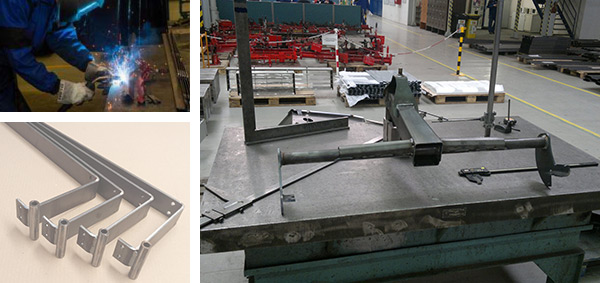

Construction

Designs of templates and simple jigs that make production easier, more accurate and cheaper.

Creating 3D models according to PDF drawings of customers and creating developed areas of sheet metal parts.

We use the SOLIDWORKS version 2017 program, which enables parametric modeling, creation of drawing documentation and 3D visualization.

Supported input formats – DWG, DXF (supplemented with PDF).

CNC programming

Creation of cutting plans and CNC programs for laser and cutting machines.

Creation of cutting plans and CNC programs for laser and cutting machines.

Supported input formats – DWG, DXF.

Technology

Preparation of technical documents for the calculation of price offers.

Preparation of technical documents for the calculation of price offers.

Creation of production processes and instructions.

Operational solution of technological problems of production.

Technical possibilities

Surface cutting of material by laser machine

Laser cutting of stainless steel, steel and aluminum sheets (or cutting of foil sheets)

Surface cutting of material with a punching press

Punching, cutting and punching of sheets on a Trumpf punching press using special tools.

Sheet metal bending on press brakes

Bending is a forming process in which a material is permanently deformed to a different bending angle with less or less rounding of the edges. We perform sheet metal bending on NC hydraulic press brakes with the help of special tools – punches, matrix.

Manual welding

MIG, MAG welding

TIG welding (TIG)

Welded material: carbon steel, stainless steel, aluminum

Manual spot welding

Locksmith workplace

Pressing of connecting elements into sheet metal (nuts, screws, riveting, gluing of rubber components, including complete assembly of assemblies according to customer requirements)

Powder and wet paint shop

Powder coating – automatic line for applying powder coating on metallic materials

Powder coating – automatic line for applying powder coating on metallic materials

Wet painting – wet painting process on metal and plastic materials- We provide galvanic pretreatments in cooperation

External cooperation

Galvanizing (blue, yellow, black)

Anodizing

Metalworking

Blasting

Contacts

METALKOVO a.s.

Pražská 1602/7

678 01 Blansko, Czech Republic

IČO: 29277485

E-mail: info@metalkovo.cz

E-mail: invoice@metalkovo.cz

E-mail: sales@metalkovo.cz

E-mail: kariera@metalkovo.cz

Web: www.metalkovo.cz